3D Printed Insoles

3D printing is a rapidly developing technology that is being used in a wide variety of applications, including the production of insoles. 3D-printed insoles offer a number of advantages over traditional insoles.

Production

3D printed insoles can be made from a variety of materials. The choice of material will depend on the specific application. For example, plastics are often used for 3D-printed insoles that are designed to be hard-wearing, while softer materials are used to provide comfort. Your clinician will help you decide which is the most appropriate material for you.

At the Buchanan Clinic we design all our own insoles in our dedicated CAD system.

Advantages

3D printed insoles offer a number of advantages over traditional insoles. First, they can be customised to the individual wearer's foot shape and needs. This is important because everyone's feet are different, and a one-size-fits-all insole is not always the best solution. Second, 3D-printed insoles can be made from a variety of materials, which allows for the customisation of their properties.

For example, an insole designed for athletes may be made from a more durable material than an insole designed for everyday wear.

3d Scanner for direct foot scanning

Greener

3D-printed insoles also offer several environmental advantages over traditional insoles. First, 3D printing is more sustainable than traditional manufacturing processes. As a result of the reduced waste, 3D printing can help to conserve resources and protect the environment.

Clinical Benefits

3D printed insoles are a promising new technology that has the potential to improve the lives of many people. They can be more comfortable, more effective, and more durable than traditional orthotics, and they are becoming increasingly affordable. As the technology continues to develop, we can expect to see 3D printed insoles become even more popular in the years to come.

Here are some additional benefits of 3D printed insoles:

- They can help to improve balance and coordination.

- They can reduce the risk of injuries.

- They can help to relieve pain and discomfort.

- They can improve the overall quality of life.

Disadvantages

The production of 3d printed insoles is still in its relative infancy, and at this stage, it can only replicate some insole that is traditionally made. At the Buchanan Clinic, we believe in using the best option to treat each individual person. Our clinicians will use the most appropriate production method for you.

Do you make 3d Printed Insoles ?

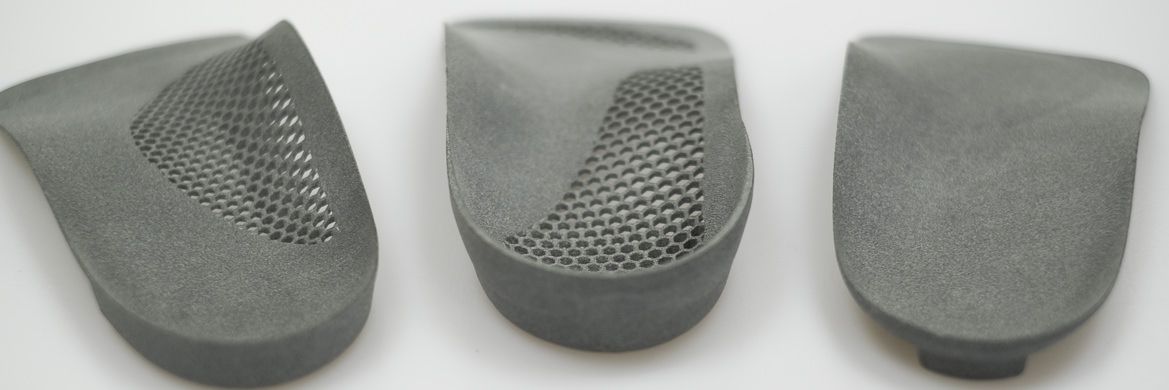

At the Buchanan Clinic we have been using hard shell (plastic) 3d printed insoles for a number of years. We love how thin but supportive they are.

We have recently invested in additional 3d printers to allow the production of soft 3d Printed insoles.

Printing in soft materials allows the production of insoles that were previously not possible with multi-density areas, offering support and comfort.

Soft 3d printed insoles

Book an appointment

If you are experiencing foot pain or biomechanical issues, you can book an appointment with one of our clinicians.

Do you provide assessments?

At the Buchanan clinic we offer specialist assessments in both Glasgow and Edinburgh. You can book online or give us a call on 0141 440 1999

Book an Assessment

Contact us

Online Booking: Buchanan Clinic Appointments